NDT – Phils., Inspection Services Corporation

NON DESTRUCTIVE TESTING

Balanced Field Electromagnetic Technique (BFET)

HRSG UNIT (TUBE TO HEADER WELDS)

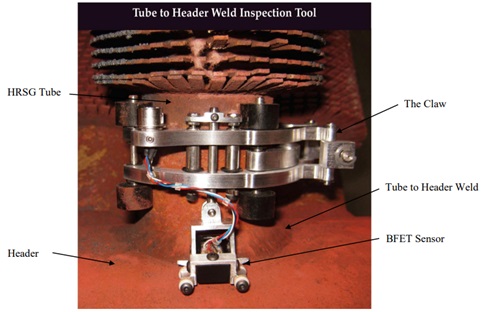

• Balanced Field Electromagnetic Technique (BFET) to inspect the tube to header welds of HRSG units. The BFET probes and cameras are placed on the welds using a C-clamp housing called “The Claw” that attaches to the tube. Once attached to the tube, the assembly moves circumferentially around the weld to detect cracking, lack of fusion, porosity, and other defects.

• Alternating Current Field Measurement Technique (ACFMT) as per ASME V Article 15.

• Used anywhere cracking is an issue, including both ferrous and nonferrous metals

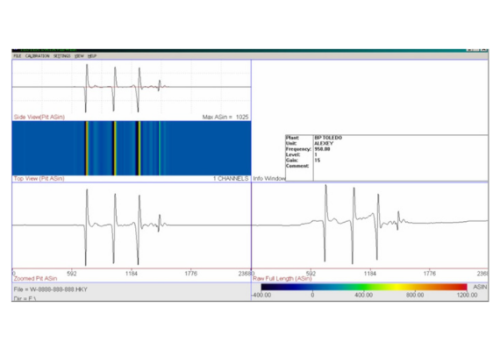

• Signal processing eliminates liftoff and noise signals

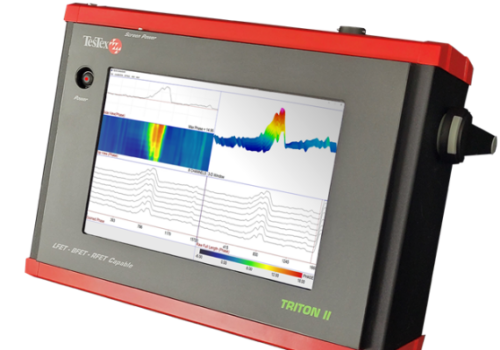

• Supports single and multi-channel scanners up to 8 channels

• Multi-channel scanners give real-time high-resolution imaging of flaws

• Detects flaws within 1/8″ of surface or 3/8″ with deep penetrating scanner

• Scans welds of similar and dissimilar metals