NDT – Phils., Inspection Services Corporation

NON DESTRUCTIVE TESTING

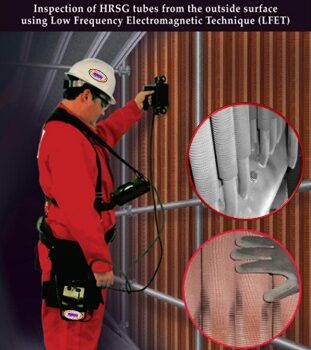

Low Frequency Electromagnetic Technique (LFET)

HRSG FINNED TUBES

• The Low Frequency Electromagnetic Technique (LFET) is able to detect and quantify wall thinning on HRSG finned tubes from the outside surface through the fins. The LFET scanner moves along the tube as it measures the strength of the return electromagnetic signal that is emitted into the tube by the scanner’s exciter coil. The carbon steel fins allow the signal to penetrate into the base material of the tube. To perform an examination of HRSG finned tubes with pitting and general wall losses. The results showed that the LFET can detect localized wall losses such as pitting as well as general wall losses like flow accelerated corrosion.

WATERWALL TUBES

• Approx. 2000 linear feet (610m) per shift

• Uniform rust, scale, and coatings are not a problem

• Quality high pressure water blasting is sufficient for coal fired boilers surface preparation

• Easily detects corrosion cells, hydrogen damage, caustic gouging, pitting, and general wall loss

• Inspects both ferrous and nonferrous tubing

• Inspects up to 3/4" (19mm) thick carbon steel

• Can scan material with coating thickness up to ½ inch

• No couplant needed

• High resolution color graphics with 3D display

• Variety of contoured scanners to fit any tube diameter